Grinding Machine

Grinding Machine

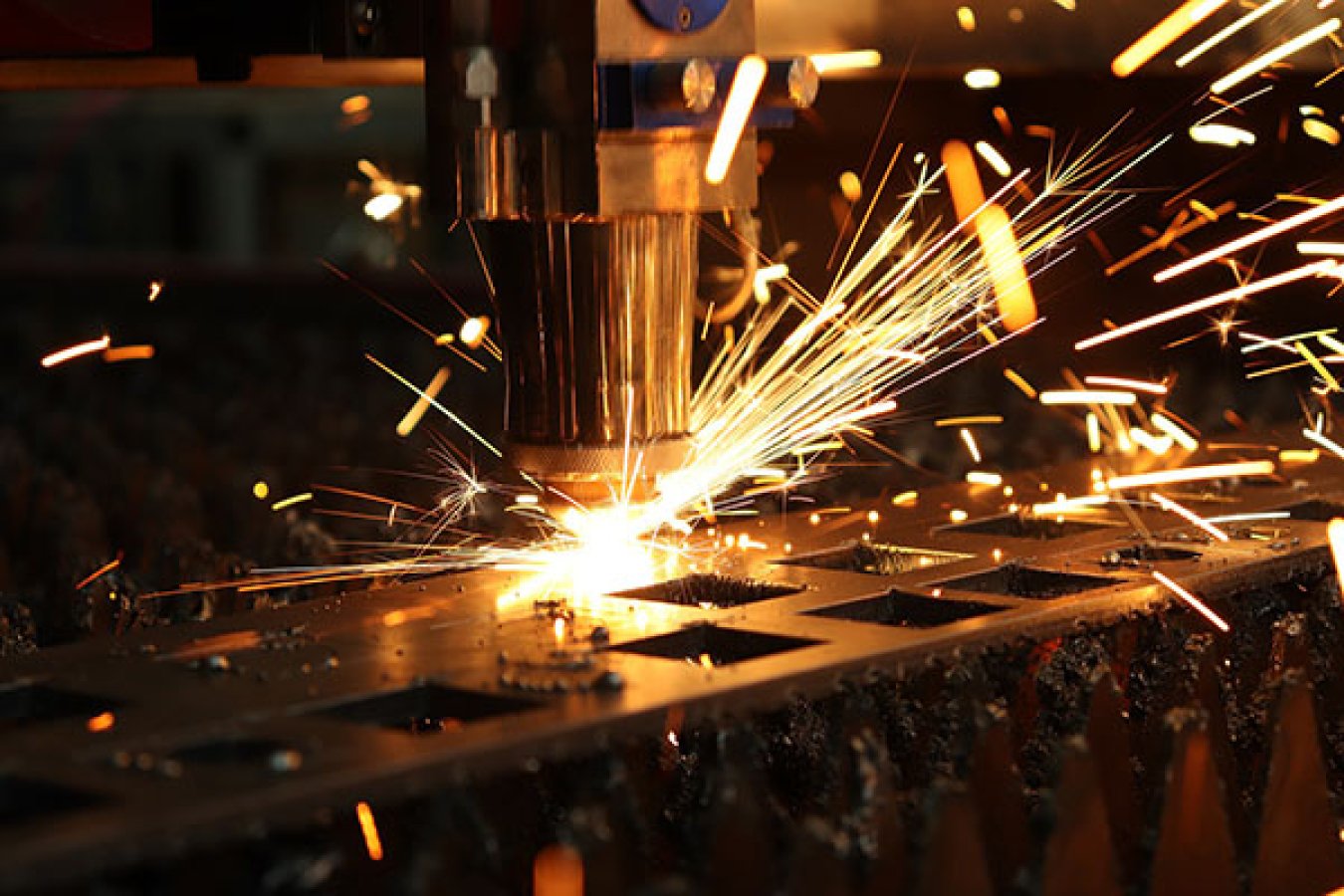

This

is the machining process with cutters that has hard and abrasive grains

manufactured in certain forms. Grinding machines are manufactured for machining

as these machines facilitate processing the metals that are frequently used in

today’s industrial world. The grinding process is done on a bench and this

bench is called a grinding machine. Grinding machines are used for

manufacturing workpieces with dimensional sensitivity and high surface quality.

What Does Grinding Mean?

Grinding

is one of the last and highly important steps of manufacturing. Because this is

the last step that involves retouching for aesthetic look and ease of use. The

machining which involves correcting the bulges to obtain smooth surfaces is

done at this stage. This machine is used after the milling machine and the

desired surface is obtained.

Grinding Machine Types

Surface

Grinding Machine: This machine is used for grinding the

surfaces of the workpieces. The

machine can be horizontal or vertical.

Centerless

Grinding Machine: This machine grinds the workpiece between

two stones without fastening the workpieces.

CNC

Grinding Machine: These machines have an automatic grinding

system. These are used for

surfaces.

Cylindrical

Grinding Machine: As the name suggests, this machine is

suitable for cylindrical, conic and curved surfaces. This machine can be used

inside or outside the workpiece for grinding.

What Are the Advantages of Grinding Machines?

In the past, the machining processes were

done with stones. Since this process was based on human power, it was extremely

slow. Now, there are grinding machines and it is possible to easily process

workpieces that require high sensitivity. Here are the advantages:

·

The large and heavy workpieces can be ground easier.

·

The grinding surface area increased.

·

The machines offer high grinding volume in a short time.

·

The machines offer ease of sensitive dimensions.

What Are the

Properties of a Grinding Machine?

·

The workpieces must have sensitive measurements.

·

The solid surfaces of solidified materials must be dried.

·

The surface errors for cylindrically parts must be eliminated to improve

mechanical properties.

·

The machine must create high-quality and shiny surfaces.